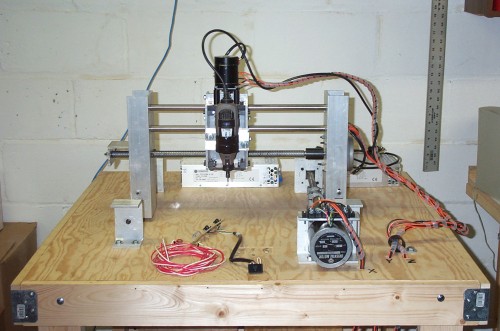

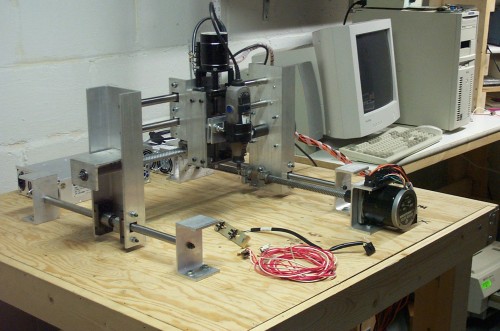

Thinking about building a CNC machine? Hacked Gadgets forum member, Aaron Bowser has a site loaded with information on how to build one. Not only is there helpful information about his design, there is also a vast number of links to other resources.

“The mechanical design of the machine was based on a survey of CNC machine websites and on the availability of used and surplus parts. A y-axis gantry style, similar to the one used by Axxus Technologies, was selected. The stepper driver board currently used in this project was created based on the application notes from the UN5804B stepper driver from Allegro Microsystems. Each board is controlled by a step and direction signal. The UN5804B chip has been hard wired to run in half stepping mode with output constantly enabled. The UN5804 chips are only capable of driving 1.25A max current, but all of the motors that are used have current ratings above this value. In order to solve this problem, I added IRC’s IRL540 power HEXFETs to drive the motors.”

Permalink

Nice! I’m working on mine too, using parts scrounged from work. So far i have all the motors I’ll need (3+1 for a spare) some steel shafts and some linear bearings for them and some other parts and bobs.

If your planning on making a CNC Milling Machine, here is a tip: A lot of the components can be scrounged from ANCIENT line-printers, including the controller chips. The Memorex-Telex ones are my current favorite. Just remember: Never throw away anything electronic, motor related, or motors. The plastic shell, and the other crap you can get rid of. Each printer I part out takes up a 10″ square box that I get from the post office for all my eBay stuff. The printer itself is about as big as a push-mower.

Your local junk-shop (Thrift-stores, Salvation army, electronic surplus warehouses, Mr. Fix-IT) would be glad to help you out with purchases. When my machine is ‘finished’, I will post my log that I am keeping about it here.

I’m shooting for a total-cost of under $800 USD. As of now, I’ve spent exactly zero dollars on it.

Permalink

Hey Aaron, I just wanted to say that this is a very neat project. I liked it so much, I am building one for myself. Right now, it is just some spinning motors interfaced with the computer. Already, I can see where I want to come up with a new board layout other than the one I have. I would like to put all of the stepper drivers on the same board, and integrate a joystick into the design, allowing for manual control of the motors through a microcontroller. This has also sparked my interest in some other designs that may be integrated into my workshop very soon!

Thanks!

Permalink

My website with details on this machine has moved to http://home.comcast.net/~bowzacnc/.

Thanks,

bowza

Permalink

Thanks, I will update the link.

Permalink

Great machine!!!! It’s definitely one of the best designs out there. Simple, neat, and very attractive. I’m conducting research on building one for under $1000.00. Wish me luck!

Permalink

sir this topic was excellent great great of 1000times great

can you provide the clear idea about computer numerical controller machine

Permalink

price list cnc

Permalink

price lict cnc from egypt