If you ever wanted to do some laser engraving, this project might be of some interest to you. The circuit is basically a variable voltage regulator that is powering a high power laser. I would highly recommend laser goggles when experimenting with devices like this.

“This laser will immediately BURN AND CUT anything you put in front of it faster than a hot knife through soft butter. And, a laser is a light beam, so it will REFLECT OFF OF ANYTHING SHINY OR REFLECTIVE AND THEN BURN WHATEVER ELSE IS NOW IN ITS WAY. You’re not going to cut shiny foil or anything else that reflects light unless you want a quick trip to the Emergency Room. Treat this with the respect you would give any powerful tool.

Put something under your work that won’t burn, or you don’t care about. A sheet of plywood is disposable, but cheap sheetrock drywall is meant to hold flames down (the white side, not the paper side). Have somebody at Home Depot show you how to easily score drywall and snap it into small pieces rather than try to cut it. Makes it easier to get it home, too.”

Permalink

How to make/get a high powered laser for cheap

Permalink

Speaking as a x-professional laser nerd this article, although well written (lengthy details) has a lot of issues.

First. The article makes it sound like, OMGz the laZer will blast through anything !!1! He is using a 658nm Diode from a DVD burner, that will give you 200mw for a little while. This is enough to slightly scorch dark paper, wood, It will not burn a hole through your table. As for cutting it would be able to cut through black paper or perhaps electrical tape, again it has to be a dark color and not more than a couple of thousandths thick.

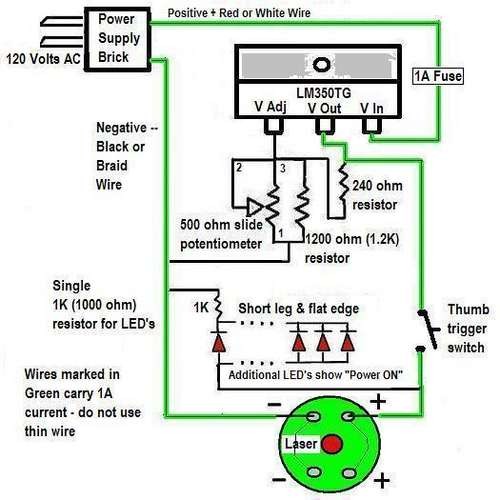

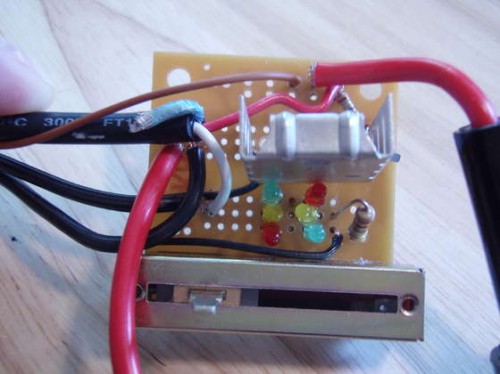

Second. The diode driver he designed is a sure fire way to bake a laser diode. There is no current limit, diode over voltage protection, or esd protection. His diode will not last long. Laser diodes are finicky beasts and are totally not forgiving to poorly designed drivers. Using a crappy scavenged slider pot is just plain a bad idea! The difference between maximum power out and a toasted diode is going to be about 1/16 of an inch of travel. I would be willing to bet his is cooked- the reason for no pictures of the results.

Third. Assuming he didn’t bake the diode, is using a dark material to “etch”, with the low power of this thing the pantograph approach will make it very hard to maintain a steady rate of feed to get anything more than burnt spots and thin lines. In other words crappy output.

I give this project a D-

c

Permalink

neat

Permalink

No current regulation = dead laser diode, unless it has a built in resistance to it. But even then, it will just take longer (but not too long) to burn out. In the mean time it will get very hot. Also, you do not need more than 1 LED for power indication, use a larger resistor. From the way it is set up, it looks like he did not have a larger resistor, since he used a slide pot. (Vout-Vled)/I = R for 1 LED series.

Permalink

Chad knows what he is talking about

Permalink

can someone please provide me with specs on dvd laser diodes?

all of the cr roms I have worked on dont have this high an output. could use a bit more data on dvd rom laser diodes. and I agree with chad about current limiting- but chad are you sayin he should use a larger current limiting resitor or should he get elaborate with say triacs or some sort of current threshold detector?

Myself I would go with say a micorpocessor control current control-

Also I would like to suggest if he has not already done this to make an adjustable duty cycle- make it pulse rather than constant and put just a big heat sink on like like some kind of copper tubing maybe even fill the copper tubing with some liquid maybe alcohol(liquid cooling is really starting to catch on in pc circles and also car audio amps IM am told) . lock it down with heat sink compound and screws in the chasis and you have a better device. also you could run an inductive charging device. where when you place it in the craddle it charges by using a magnet field- mutual inductance through a sort of air core transformer deal. that way you dont even have to plug it in.- not highly effecient but it provides electrical isolation. and just a cool way to charge devices. Electrical isolation with this type of device is a good idea because it pretty much eliminates power surges. and those diodes can be spencive to replace I am sure.

please any web sites with information on these could be helpfull to me specs and what have you. I need more or less catch up on current laser diode tech I suppose…

thanks

Veronicca

Permalink

TO CHAD SINCE YOU SEEM TO KNOW SO MUCH – HOW ABOUT A CIRCUIT THAT DOES IT RIGHT

Permalink

TO GKRON

FIRST OF ALL, YOU NEED AT LEAST 20W CW POWER (OVERDRIVEN IN IMPULSE MODE) TO CUT ANYTHING. THAT IS, 20 PIECES OF 1W IR DIODES, 22USD EACH, THAT IS 440USD UPFRONT. SO THE BACKYARD-GROWN MOTIVATION THREAD IS BROKEN.

ALL THIS GIVEN THAT YOU CAN MIX THE BEAMS TOGETHER BY YOURSELF.

THAT IS KINDA COMPLEX.

NOW WHAT ABOUT STARTING OFF WITH A SIMPLER TASK SUCH AS SWITCHING OFF YOUR CAPS LOCK OR GETTING OFF THE SHIFT KEY?

Permalink

This laser will immediately BURN AND CUT anything you put in front of it faster than a hot knife through soft butter. And, a laser is a light beam, so it will REFLECT OFF OF ANYTHING SHINY OR REFLECTIVE AND THEN BURN WHATEVER ELSE IS NOW IN ITS WAY. You’re not going to cut shiny foil or anything else that reflects light unless you want a quick trip to the Emergency Room. Treat this with the respect you would give any powerful tool.

Put something under your work that won’t burn, or you don’t care about. A sheet of plywood is disposable, but cheap sheetrock drywall is meant to hold flames down (the white side, not the paper side). Have somebody at Home Depot show you how to easily score drywall and snap it into small pieces rather than try to cut it. Makes it easier to get it home, too.”

Permalink

hi my name is duc want your shemetic and print will you sell that laser engravel cutter for cheap see you write email me at

duc10051959@yahoo.com

Permalink

Did you know that you can burn ants with a magnifying glass in the sun? You could put 50,000 more LEDs on your board and put a magnifying glass on it and then it might melt ants. Plus, then you wouldn’t be frying your eyes from the dangerous IR levels coming out of a cheap laser with no filter. Keep in mind people… you can’t just get “laser goggles”… you have to get goggles matched to the precise wavelength of your laser, with IR protection. about $200 (two-hundred dollars) will get you a cheap pair of inferior goggles. If you value your eyesight, you can pay much more.

This diagram for a cutting laser may work for a couple seconds. It will feel hot on your skin, possibly leave a red mark. Black tissue paper might burn, black matches might catch fire.. but it’s only going to do it for a couple seconds. Probably won’t last long enough to take pictures of it burning anything…Which is probably why we don’t see any pictures of it burning anything.

But, we all know everyone is going to try and build one of these anyways, so at least put a capacitor and little resistor on the driver board to filter esd, prevent inrush current damage to the laser diode, and maybe even use a simple 555 timer to pulse it maybe at 100hz. Might help prolong the life of the “way overdriven” laser diode.