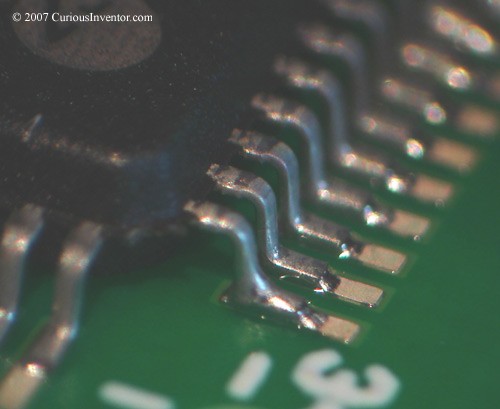

If you are thinking of doing some surface mount like AnotherHackMember has just done. This Surface Mount Soldering Tutorial video at Curious Inventor is a must watch. Have a look at the other information that is available at this site to understand other areas of soldering and board repair.

“video demonstrating Surface Mount Soldering with inexpensive equipment. Includes soldering of a 603 resistor, PLCC, 44 pin QFP, 208 pin fine-pitch QFP, desoldering using hot air and ChipQuik®, and prototyping with SchmartBoards”

Thanks for the tip David!

|

|

Permalink

wow thats great, is good to know

Permalink

Excellent tutorial ! I remember we had to do that with a friend with a FPGA but we weren’t soldering masters, we did it the hard way, without flux, one pin after another under the microscope. It took an hour to solder the whole chip + another hour to remove the shortcuts… Damn, this would have been fast if we had known your method !

Permalink

So far, I haven’t found “exactly” what I am looking for. I’m looking for guidance on soldering edge-connectors. My google search “edge connector and soldering” brought me to hackedgadgets. I have training and some experience in soldering, but our washer is down and I need to resolder (tin?) the edge connector to the CCU board. I’ve never had to do this before and just wanted to find some guidance. Surprisingly, there weren’t many hits, but thanks to hackedgadgets, I think I’m on the right path.

Permalink

Hi Don,

The connector you have is surface mounted to the PCB and the solder connections are under the device and can’t be accessed from the top surface? If you can see the connections touch them up by reflowing a small amount of fresh solder into them. If they can’t be seen it gets very tricky since you should remove the component, remove the old solder using solder wick, apply new solder paste to the PCB and resolder the component in place.

The issue is when you remove and replace the existing component. Since you need to apply heat to do that there is a chance of desoldering the surrounding components. I have never done this type of delicate circuit repair before though so there may be a simpler method that I don’t know about.

Permalink

Thanks for your reply. I’ve re-soldered the edge-connector and re-installed the CCU board. Our Kenmore Elite, model He4t, washer is working like it did 4 years ago when it was brand new. I “did” apply flux paste and with a toothpick – the soldering points were only about a millimeter apart – and then use what I looks like hair-thin rosin core flux. (I inherited this and the paste from my father, so who knows if you can still even buy it.) The surface mount components looked good, which is reportedly much better than most of these foreign-made boards. By the way, I used denatured alcohol to clean off the flux… This caused a faint, milky discoloration around the contacts. Anyway, thanks for your reply.

Permalink

Good to hear you got it fixed. Another piece of equipment that escaped the landfill. 🙂