Remember the Fisher & Paykel Smart Drive Washing Machine Wind Generator from earlier this month? Well it looks like there is more uses for those motors! How about recycling 3 used washing machines into a huge powerful CNC machine. It takes a bit of work but apparently the 3 phase stepper motor makes for a good and accurate CNC motor.

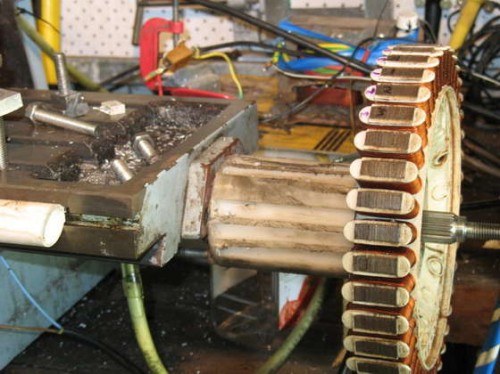

"The motors from a fisher and pykel washing machine are removed along with the control board. Three motors are required. Connecting the stepper motors to the HM30 machine The hole at the end of the plastic housing the motor spindle, slips over the end of the x,y axis on the mill table. The spindle is shortened and drilled to allow the shaft from the table to slide into the shaft from the washing machine. A tapered pin and hole, hold the two together. The motor is basicly a three phase stepper motor. Good luck finding a driver for it. A driver can be made by using the FETs from the washing machine controller. A PICAxe chip (see Oatley electronics) is programed to take the step and direction pulse’s and energise three outputs for the three coils (5 input/outputs fits on the PICXE08 model, this is programmed with free software on the serial port of the PC). The three outputs are used to drive a darlington pair in the chip ULN2003 (drives up to 8 outputs), this in turn drives our FETs from the washing machine."

Permalink

Very cool. My only concern would be possibly getting your clothing caught on one of the motors during a long run. (as opposed to a jog) I imagine those motors develop some serious torque.

Permalink

Yeah, I would definitely suggest a big, red emergency stop button.

Permalink

You better put some plexiglass or something between the motor and mill, to prevent chips from getting in the stator or between it and the rotor. If you don’t it will not last long.

As Pouncer and Shadyman say, you definitely need a shield so you don’t hit the rotor, and an easily-reachable e-stop buton. The fins and holes in the rotor help cool it, so you need to take care that the shield does not block airflow.

In a washer, the rotor is always spinning when energized, so it can cool itself. In CNC it is often energized and moving extremely slow or not at all. You might need a muffin fan to provide airflow.

Permalink

Video would have been nice in the instructable.

Permalink

The Fisher & Paykel Smart Drive is very Kool! Can any one tell me where you can find used machines. I’ve never heard of that brand.

Permalink

They started from Australia but are now in the US also.

http://www.fisherpaykel.com/global/about-us/our-products.cfm

Permalink

Actually, F&P makes parts for Maytag/Whirlpool/Kenmore. If you have a toploading, high efficiency washer from one of those three, chances are it has “Fisher and Paykel” stamped on the motor parts. I’m not sure just how much of the washer they make, it’s POSSIBLE that they make all of it. I had to get parts for my Kenmore, and was quite suprised to find that most of the part numbers are common between Maytag, Whirlpool, and Kenmore. I thought they were competitors, but obviously not.

Permalink

I wouldnt think to find a stepper motor in a washing machine.. whats the point of that ?

Permalink

Hi Marco,

If the machine is discarded the motor is free. 🙂