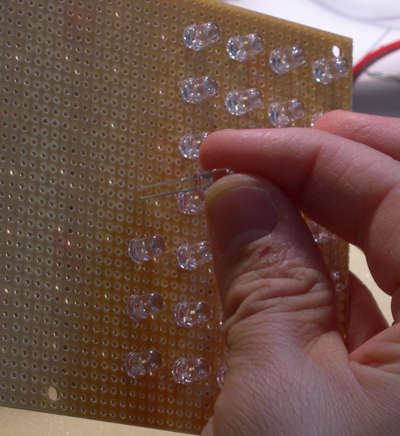

When you are making DIY printed circuit boards, one of the popular methods requires UV exposure. Many systems use lamps that can give off lots of heat and be expensive to replace. Djhamer has provided plans to make a UV LED system that is double sided so that you can expose double sided PDBs without having to flip and repeat half way through the process.

"A UV exposure box is an extremely useful piece of kit. It can be used to make proper PCB’s. It can also be used to make other things such as intricate photo etched parts (a subject for another instructable). The trouble is they can be a little pricey for the hobby enthusiast especially if you want the double side type.

This instructable outlines the construction of a double sided UV exposure box using the recent generation of high brightness UV LEDs.

Why use LEDs?

LEDs are far more energy efficient than either incandescent or fluorescent lamps offering between 5-10 times more efficiency making them cheaper to run and kinder to the environment. They also (unlike fluorescent tubes) do not contain mercury. LEDs have a far greater life span than the other types of lamp measured in decades rather than months. The frequencies being emitted are also in a tighter band making UV LEDs safer than the traditional UV tubes. There’s also just something cool about LEDs, I can’t put my finger on it, but ever since I was a kid I’ve found them to be one of the more fascinating electronic components."

Via: Elektronika

Permalink

I’m curious as to whether the author has used this to expose boards at all and what kind of resolution they’ve gotten out of it. I’d expect some serious problems with fine lines due to UV sources coming from multiple directions and partially undercutting the film, and with exposure consistency in general due to the inverse square law.

Permalink

Whoops, did not immediately notice that the LED banks were set back enough to limit unevenness. I might still be concerned about thin traces and sharp edges. Better or worse than iron-on toner?

Permalink

I use a “compact fluorescent” type of blacklight to expose my PCB’s. Messy, but it works perfectly. This however is a very clean and simply beautiful construction. Since the transparency is put back-to-back with the resist, lighting angle is not really an issue.

Any comparison of photolithographic methods with iron-on is simply laughable. Iron-on is not a technology.

Permalink

Normal compact fluorescent tubes coupled with tracing paper do a very good job with exposing PCB traces. You just have to know how to properly do it.

Permalink

Hi blued888! Do you have any hints to share? While my technique is more or less stable, I sometimes have trouble with toner sticking to tracing paper: there are microscopic gaps, or even smearing. It’s mostly evident with thin (0.2mm) traces. I suspect that I just have a crappy printer, but who knows, what if there’s some trick to better toner adhesion. The printer is Canon-something, cheap.

Permalink

svofski, I’ve used HP LaserJets (a 6L and a 1010) to print on tracing paper and have had no issue at all with toner adhesion. You have to pick the right tracing paper thickness to print on. Don’t use ones that are too thin. Either they become warped due to the heat or the toner probably won’t stick well.

I am unsure of what thickness I used. I haven’t been PCB-etching lately. Did it a couple years ago during college.

Permalink

Thanks blued888! I wouldn’t say that my results are bad, but I wouldn’t mind some improvements so I ask. It’s a good idea to look around for different types of tracing paper, indeed.

Permalink

Any info on how large board can fit into the device? I have about two parcels of 12mW 395nm UV LEDs, which might be used in similar device. What might be the exposure time I wonder…

As the author warned, these LEDs are (really) harmful to one’s eyesight. Use UV-protection goggles AND install safety cut-off switch to the lid of the exposure box to prevent any accidental exposure to the UV light…

Symptoms might not appear immediately, but include burning sand-in-the-eyes-sensation, fogged/blurred vision and halos around bright light sources. These symptoms might go away in case of mild exposure, but in any case, one should be very careful when toying with these things…

The resolution (reproduction from transparency to board) should actually be very good with UV LEDs since they generally have very narrow beam width. This means the shadows cast by the transparency aren’t really that much scattered, which would be the case with fluorescent tubes…

There’s of course one benefit for using LEDs: low operating voltage means you could run this through 12V battery with simple regulator, so UV LED exposure device is potentially more portable than any of these suitcase fluorescent tube models…

Permalink

“LEDs are far more energy efficient than either incandescent or fluorescent lamps offering between 5-10 times more efficiency”

That’s not true.

Most visible LEDs are slightly less efficient than fluorescents and UV LEDs are much less efficient than fluorescent blacklights. Fluorescent blacklights are more efficient than visible fluorescent tubes and UV LEDs are much less efficient than visible LEDs.

UV LEDs are still a new technology. UV fluorescents have been around for years. Fluorescents are better for UV than visible because there’s a lower Stoke’s shift converting the UVC light from the mercury arc to UVA than the visible region.

Black light fluroscents also emit shorter wavelengths mainly 360nm to 380nm which is better for exposing PCBs than the near violet light emitted by most UV LEDs.

I would imagine that you would get better results using two 4W black light tubes. It will also use less energy, assuming you use a decent switching ballast.

LEDs do have the advantage of being more robust and if one of them breaks you can still use it. They are also safer because they’re not made of glass.

The fact that fluroscents contain mercury is a non issue because the amount found in a small tube is below the safe daily exposure limit.

Permalink

Not true. LEDs are more effecient than fluorescent, there are few reason: Some switching ballasts can consume more than 4 Amps, just to stuff 20 – 100 milliAmps into UV fluorescent tube (while LEDs only eat 3.5 Volts at 20mA Powerful ones, like Cree XLamp, sucks around 350mA). Blacklight fluorescent just simply waste a lot of electricity by just emitting vacuum UV and/or Infrared (Yes, there are some IR in there.) that Phosphor refuses to convert to UVA (375nm UV). Also, it simply get so hot, to some point it would require fan cooling, if left on way too long.

Also, adding the insult onto injury, Blacklight fluorescent would just conk out after 2,000 Hours and is easily breakable.

UVA LED are, in fact, better than the fluorescent, why?

Life exceptancy, and safety of High-voltage handlings. No need for nasty 340 Volts AC just to light that up. And, 365nm UV LEDs are cheaper if you just look harder.

Permalink

These LED have not enough radiated power (Watts), my experiments have give me bad results.

The photo etching method needs 60 Watt radiated power at 10 cm target distance, also the wavelength must be 340nm (Near UV) with maximum wavelength 254nm, if you are going to use far UV light tube (190nm for example) the radiation will pass though the film (and though the plastic box) destroying all the photosensitive material, and causing cancer to you! You can feel the radiation of these UV Lams as small droplets to your skin, so…..avoid these UV lams (sterilization UV Lamp) and try to use regular UV lamps or Power UV LED for best results.

Permalink

Still, true. But if you’re going to use sterilization tube, you’re going to waste several watts here! Because, there are way too much free-path collision against lots of molecules in the air while trying to get Extreme UV onto your board, thus attenuate the useful flux of Uv emission. (I have worked with X-ray before so I know what it’s like trying to get UV that’s very close to that particular wavelength. So it’s pretty much like taking shotgun to the PCBs. X-ray etching on the PCB can be done, but for you mortals, FORGET IT. You will need damn good cooling and LOTS of Lead shielding and who wanna touch Lead? And, of course, you can fry yourself if you accidentally touch X-ray tube anode and ground.)

Permalink

Hello,

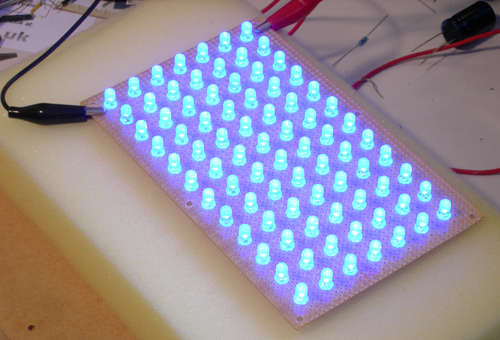

A lot of you are just talking bollocks, I’ve made a UV exposure box using about 100 UV leds from ebay running off 12v, they are about 5 inches from my pcb.

Simply print onto transparancy, flip the toner to the board and expose for 30 seconds – works like a charm. If only etching was this easy.

Permalink

Well, UV LED works plainly fine for PCB etching. People out there just don’t understand what LED is capable of. (Surprise, James, you’re not ALONE!)

Ever wonder why a 5mW laser diode is made so freaking small? That’s exitronic physics at work, baby! (That’s the reason why you shouldn’t look at UV (and IR) LED at full brightness, nor would you want with the laser diode.)

And, another things to consider: Focal points, beam waist, divergence, and transparency of scanner glass (some of them use just plainly a fused Quartz glass for you to put paper on to be copied. I would be guessing the B/W scanner would use IR LED or laser to scan the paper, if it has a Quartz window panel.) I wouldn’t want one of LED focusing badly (as in case of El-Cheapo Chinese LED), ruining my PCB work. (leave-on PCB etch mask won’t affect anything at all, but Lithography? Ehh… I would rather use TO-40 canned LED to do it better.)

LED to the power!

Permalink

“# Dr. Mario Says:

July 3rd, 2009

Not true. LEDs are more effecient than fluorescent, there are few reason: Some switching ballasts can consume more than 4 Amps, just to stuff 20 – 100 milliAmps into UV fluorescent tube”

Specifying the input current is meaningless unless you specify the voltage.

4A drawn from a 5V supply to power a 16W tube isn’t too bad.

Besides that’s nothing to do with the efficiency of UV LEDs vs tubes debate. Powering an LED using a resistor wastes a huge amount of power, if the LED is 3.5V about the power supply voltage is 6V that’s an efficiency of 58.3% which is worse than the worst magnetic ballast.

” Blacklight fluorescent just simply waste a lot of electricity by just emitting vacuum UV and/or Infrared (Yes, there are some IR in there.) that Phosphor refuses to convert to UVA (375nm UV).”

Fluorescent tubes only emit a tiny amount of IR and vacuum UV.

If vacuum UV was a problem then germicidal lamps would emit lots of ozone so will require lots of ventilation to prevent them being a health hazard but this isn’t the case.

The worst blacklight tube will have an efficiency of about 15%, the best will be closer to 30% efficient. A typical UV LED is about 10% efficient and cheap Chinese LEDs will be much worse. There might be more efficient LED prototypes in the LAB but they’re certainty not ready for the mainstream.

” Also, it simply get so hot, to some point it would require fan cooling, if left on way too long.”

I’ve never needed to use a fan on a fluorescent enclosure but overheating can be caused by using cheap magnetic ballasts and inadequate ventilation.

The same is true for some power LEDs, especially the cheap Chinese variety commonly bought off ebay. Some are also given unrealistic forward currents and have poorly written datasheets.

“Also, adding the insult onto injury, Blacklight fluorescent would just conk out after 2,000 Hours and is easily breakable.”

2000 hours? That’s just bad luck, a typical fluorescent with a properly rated ballast should last for 5000 hours, some last for over 10,000 hours.

It is true LEDs though that last longer than fluorescent tubes but it’s important to note that both get dimmer over time.

You’ll replace the fluorescents after

“UVA LED are, in fact, better than the fluorescent, why?

Life exceptancy, and safety of High-voltage handlings. No need for nasty 340 Volts AC just to light that up.”

True, LEDs don’t need a high voltage supply which is an advantage when it’s powered off a battery but it’s a disadvantage if you want to power it from the mains.

” And, 365nm UV LEDs are cheaper if you just look harder.”

Sorry, I don’t believe that.

If you buy cheap LEDs they’ll be very inefficient and much less efficient than a blacklight fluorescent.

You can buy a 2ft blacklight fluorescent tube for less than £3 ($5 US) which will produce as much UV as many hundred UV LEDs.

Don’t get me wrong, I’m not saying LEDs are crap, they’re good. Someone I know has made an LED exposure using cheap LEDs and it worked really well.

One of the advantages of using LEDs is that even if they’re less efficient than fluorescents, in terms of power in/ power out, the old emit light over a narrow angle which is used more efficiently

Permalink

Well, UV LED works plainly fine for PCB etching. People out there just don’t understand what LED is capable of. (Surprise, James, you’re not ALONE!)

Ever wonder why a 5mW laser diode is made so freaking small? That’s exitronic physics at work, baby! (That’s the reason why you shouldn’t look at UV (and IR) LED at full brightness, nor would you want with the laser diode.)

And, another things to consider: Focal points, beam waist, divergence, and transparency of scanner glass (some of them use just plainly a fused Quartz glass for you to put paper on to be copied. I would be guessing the B/W scanner would use IR LED or laser to scan the paper, if it has a Quartz window panel.) I wouldn’t want one of LED focusing badly (as in case of El-Cheapo Chinese LED), ruining my PCB work. (leave-on PCB etch mask won’t affect anything at all, but Lithography? Ehh… I would rather use TO-40 canned LED to do it better.)

LED to the power!

http://www.n-khvoq.com/vb

http://www.n-khvoq.com/topic

http://www.n-khvoq.com

Permalink

I am interested in making a double sided Photo Resist curing box using UV LEDs of 400nM Please let me lnow complete details and timing circuit etc I want to make pcb of single side copper 5″by6″. Please let me now if you can supply copper clad board also.