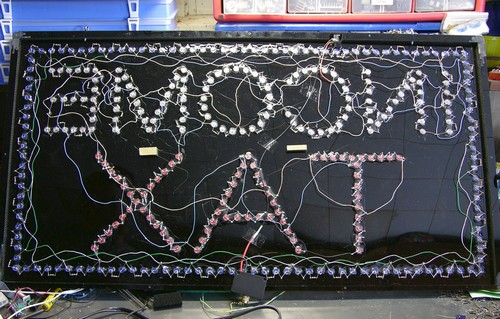

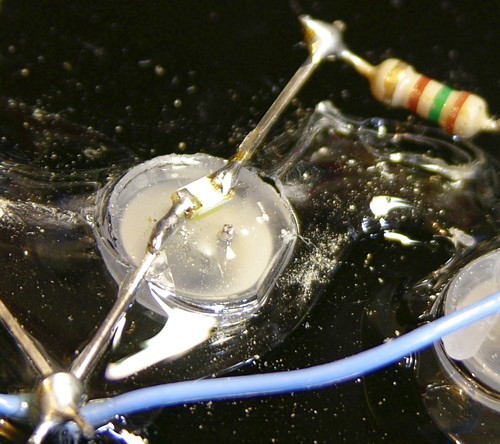

Keith has a good example of making a electronic repair with parts at hand. This 300 dollar sign was going to be thrown in the garbage because of a few burnt out and dim LEDs. After the sign was opened Keith would have replaced the 10mm White LEDs if he had some but he didn’t, his next idea was to drill out the rear of the 10mm LEDs and install some 5mm LEDs. As it turns out he didn’t have any of these either. His final solution was to mount some surface mount LEDs to the back of the existing 10mm LEDs. The result is great, have a look at the above (repaired) picture and see if you can see which LEDs were repaired.

"The sign is made of two plastic sheets sandwiching a thicker plastic frame. The front must be glued on, but the back is screwed on for repairability. The right fix would be to replace the broken LED, but I don’t have any white 10mm LEDs on hand, it would take a while to order, frosted 10mm LEDs seem to be more difficult to find (or to find clearly specified as such), and I’d have to wade through long lists of nearly-identical products searching for the one that was actually right. Immediately I thought of a way I could fix it using materials I had on hand — drill a hole into the back of the 10mm LED and sink a white 5mm LED into it. This idea made me cackle with glee, so you can imagine my disappointment upon realizing I don’t in fact have any white 5mm LEDs here. I need to get me some so I can go back and try that yet."

Permalink

Nice hack. I would have figured he would still drill out the old LED to clear any light obstruction, but I guess there was no need.

Permalink

what ? where does 300 dollar tag coming from ?

Permalink

no seriously there is only two possible ways you can to get 300$ for bunch of leds and resistors:

1)time travel in to 70’s before led was invented

2)meet rich brain stroke victim with 30% of living brain remain

well if someone willing to trow 300$ sing just because couple leds fade then probably it is stroke victim

Permalink

I don’t think I’m surprised by the condition of how it was made, based on what it looks like on the outside. “Was this thing built in some guy’s garage with stuff he pulled out of the dumpster at work?” I’d say it’s a resounding, ‘YES’

Permalink

Who was willing to pay $300 for that sign ???????????

Permalink

It cracks me up how incredulous you all are about the $300. Sure, for those of us who are able to make things, it seems like a waste, but businesses routinely spend amounts like this for a flashy sign like that.

Keep in mind the costs to have the case made, holes drilled, LEDs/resistors purchased, power supply made/bought, labor to install components, etc. Also, various fees for safety and such, shipping, manufacturing facility lease, etc. And then of course, a nice good chunk of profit. But some income tax company would much rather pay a couple hundred for the sign than have someone sit down and take time to design, purchase, and build such a sign. In reality, $300 is a bit on the high end for this sign, but good luck finding something like it for less than $150-$200.

A couple quick search results:

http://dotrixled.com/product_info.php?products_id=454?osCsid=aui7bhpuka43pnnp11vm0a75j0

http://store.everything-neon.com/ledsiintaxle.html

http://www.bestbuyneonsigns.com/index.asp?PageAction=VIEWPROD&ProdID=8972

http://www.allneonsigns.com/income-tax-led-sign1.html

Permalink

Yep what did you think LED signs are expensive. If you think this is a ridiculous price you better not look at LED matrix signs or even RGB LED displays!

Permalink

well such price will be appropriate for neon sing (2x-3x in size by the way) because you need special machinery and skills to cut glass bend it and work with dangerous materials such as mercury and calculate high voltage power supply. But this one doe not require anything above a HS student reading electronics magazine like “Make” will be able to make same or better one. And what kind of poor design is it that leds failed, I cant remember a single case in 5 year of led failure, what kind of cheep Chinese leds from dumpster they use ?

Permalink

An average LED (not extremely cheap chinese one) has life of at least 50 000 hours (approximately 5years and 8 monts) non stop work. After 50 000 the LEDs are producing 50% less light and still work. If this sign was built of good quality LEDs they wouldn’t burn out easy.

Permalink

Bah! I say forget about it, and use a lite bright!

Permalink

LEDs (the actual bulb) are all different. There are Cree, Everlight, Cree USA, NICHIA Japan, and more. The quality of these types of bulbs is what makes or breaks the warranty. NICHIA LED is notorious for lasting the longest. The longevity of the LED itself, is greatly effected by the amount of power that is being run to it. If you have an LED Sign that has the power cranked up in it, you may think you are buying a brighter LED for your window or outside, but the truth is, you are just buying an LED that is taking on more power than it should, and will burn out in the 40,000 – 50,000 hour range. A well designed, well engineered LED Sign should last 100,000 hours or 11.4 years. If a company won’t warranty their product past 3 years, there is a great chance they know that their sign won’t last that long. Look for the companies offering 4-5 year no hassle replacements on their LED’s. Those are the companies that understand the value in quality, and are they are the signs manufactures that you should deal with.