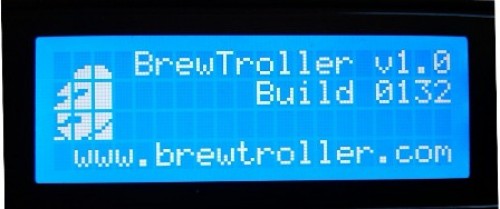

About 5 years ago I bought all the equipment to make some home-brew beer, I purchased a few different flavors of beer kits and went to work. Only one batch was drinkable, but it wasn’t that good and eventually found its way into the sink. After further reading it seemed that temperature control of the brew stages is key to achieving a good result. BrewTroller is an open source project that allows the common home-brewer to move up a notch in the sophistication of their brew process. It is based on the Sanguino microcontroller platform which was inspired by the Arduino controller.

"There are a number of savvy homebrewers who have build custom control systems for their brewery. It’s been done and that’s where we got the ideas from. What we wanted to accomplish is to create something that could meet the needs of many brewers looking for more automation, control and precision in their brewing, do it without breaking the bank and make it available to those without the electronics or coding skills needed to design a system from scratch. We ended up with a menu driven standalone device that operates much like an iPod with a rotary control that is used to scroll through menus or adjust levels.

This current development release includes the Brew Monitor which monitors the temperature of up to six temperature inputs (HLT, Mash, Kettle, CFC H2O IN, CFC H2O Out and CFC Beer Out) and controls the heat output for the HLT, Mash Tun and Brew Kettle. Each of the heat outputs can be set to On/Off mode with a user configurable hysteresis (adjustable in 1/10 degree increments) or PID mode with user configurable cycle time (1-255 seconds) and PID gain.

The main goal of the project is the AutoBrew mode. AutoBrew will walk through a series of stages (some optional) such as filling, preheat, dough-in, protein rest, acid rest, saccharifaction rest, mash out, sparge, boil and chill. Each stage would have one or more valve configurations associated with it. For example the various mash stages would have one configuration used for mash heat cycles (ie Valve outputs 1, 3 and 7 on) and one used for mash ‘standby’ cycles (perhaps recirculating the mash but bypassing a HERM coil)."

Permalink

Permalink

Permalink

Permalink

Permalink

Permalink

Permalink

Permalink

Permalink

Permalink

Permalink

Permalink

Permalink

Permalink

Permalink

Permalink

Permalink

Permalink

Permalink

Permalink

Permalink

Permalink

Permalink

Permalink

Permalink

Permalink

Permalink

Permalink

Permalink

Permalink

Permalink

Permalink