Repairing most electronics these days is pointless unless you are doing it for fun. Take an answering machine for example. You can purchase a new one for $10 but to find a fault in a dead one you could spend days of your spare time. If you have schematics and the manufactures support it can be quick and easy though, I did a short stint as a PCB repair tech many moons ago and I was surprised at how simple it was to trouble shoot very complex systems without much thinking when you had the manufactures documentation and how quickly it became more costly to repair than replace as soon as there was no documentation.

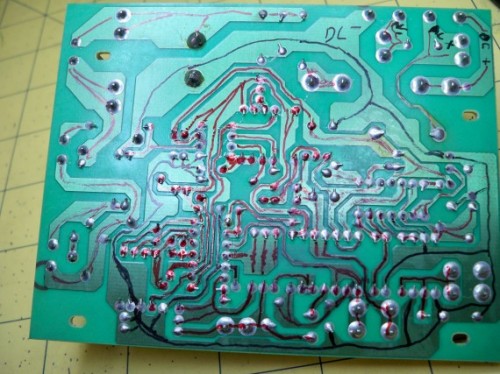

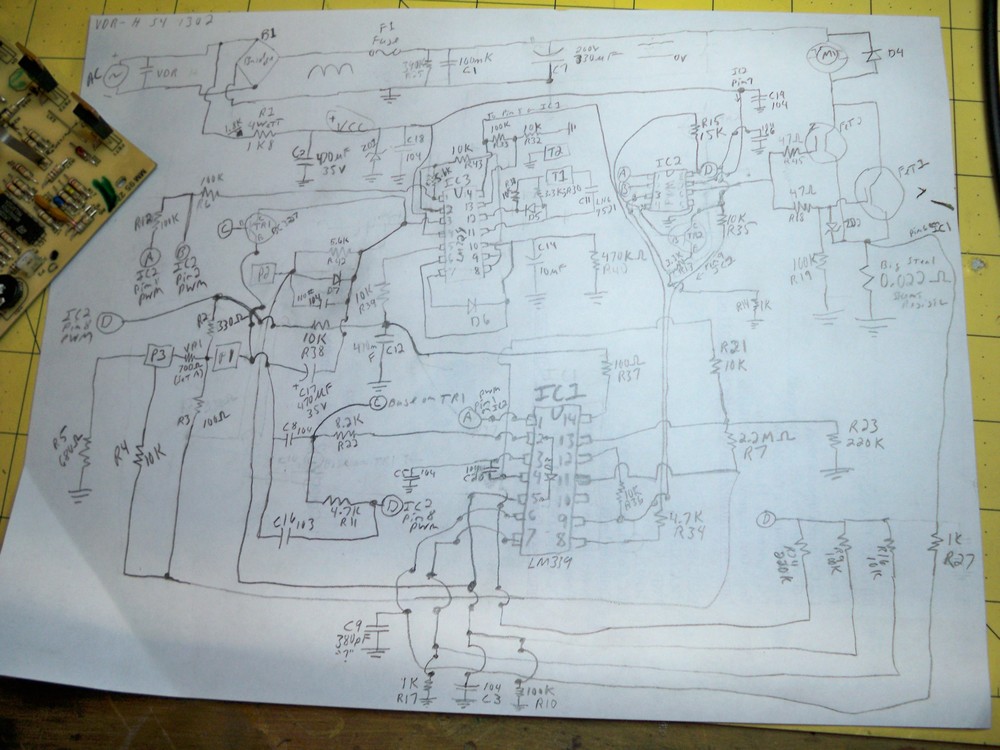

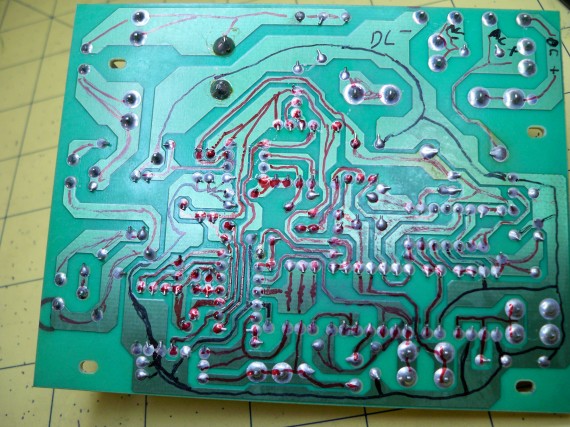

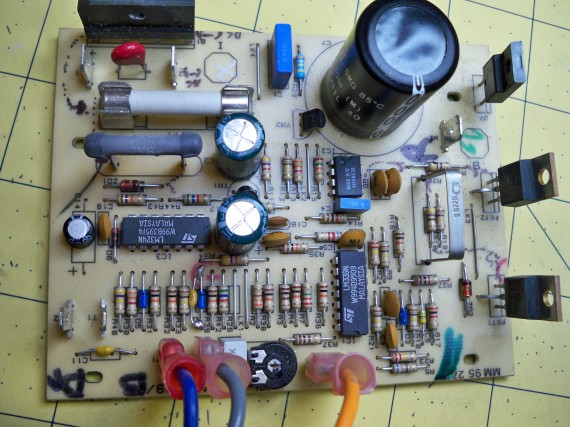

Todd Harrison has been having fun troubleshooting a motor power supply that stopped working. Of course Todd doesn’t have any of the manufacturers schematics or troubleshooting flow charts so he is doing it the hard (fun) way. Have a look at his first post where he goes over the supply and identifies the main parts and tests all of the big obvious stuff. In part 2 he goes through and traces out all of the electrical connections on the board! You can see a small image of it below but check it out in full size for more details. This is luckily a single sided board with well spaced out large components, if the board has is double sided with a mix of through hole and surface mount this challenge would turn into an alternative to completing the largest jigsaw puzzle in the world.

I was betting on a dried our electrolytic capacitor but after reading the comments in part 2 I doubt it is that since it turns out the supply didn’t die of natural causes but rather a shard of metal that found its way into the case. 🙁 Todd will be revealing what the fault was in part 3.