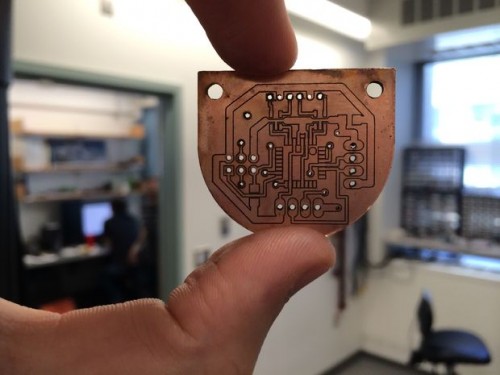

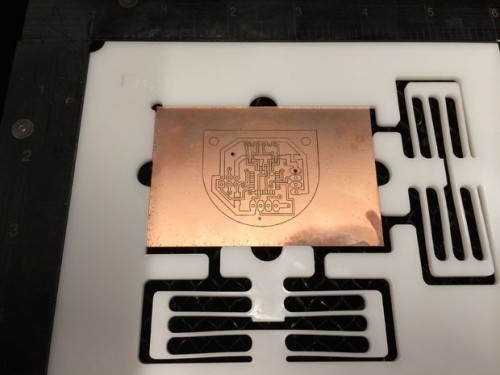

If you have a laser cutter and need a double sided PCB made the same day you can give this method a try. You first paint the PCB on both sides with spray paint to act as a etching resist. The laser machine is then used to blast away the pain to expose the copper in the areas that you need to etch, a quick flip will let you do the same in the reverse. After a quick etch and removing the paint you are left with a double sided board. A quick run through a drill press will let you complete the component lead holes and via holes. Of course this design favors SMD parts since you will have less holes to manually drill.

I have tried this technique in the past for a simply board but after some issues getting the front and rear to align properly I simply made the board out of perf board. I think the key to success is the jug that clamps the board in the perfect position each time. The laser cut adjustment spring is a great idea.