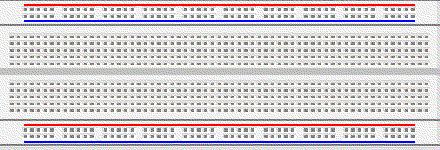

There are lots of surface mount parts out there that aren’t available in DIP format. Normal DIP format chips and various other parts have pins that are configured with a 0.1 inch spacing. Breadboards make prototyping a circuit fast and easy since there is no soldering involved, it is literally plug and play. If the connections need to be changed all you do is pull the wiring out and position it where you would like it.

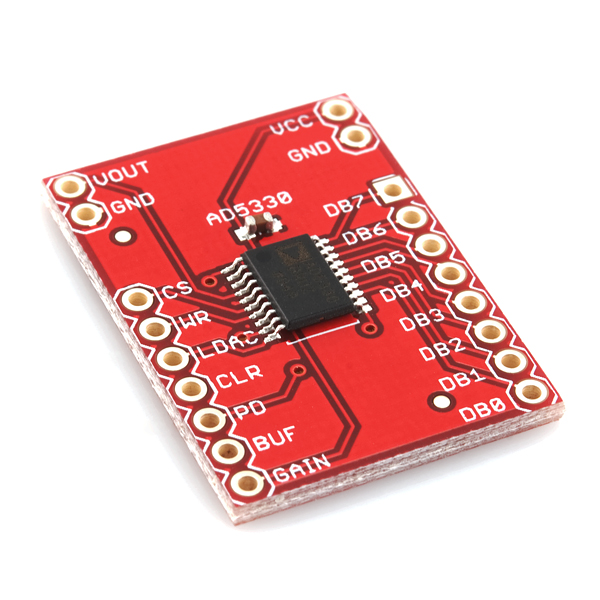

But what happens when your part is not in a 0.1 inch format? There are lots of pin converters from companies like Spark Fun that allow you to solder surface mount parts to them and they have the popular 0.1 inch pins so that you can now simply plug it into your breadboard.

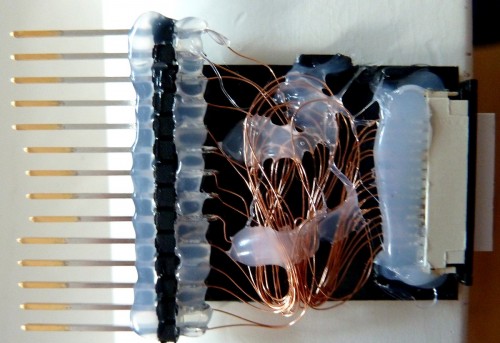

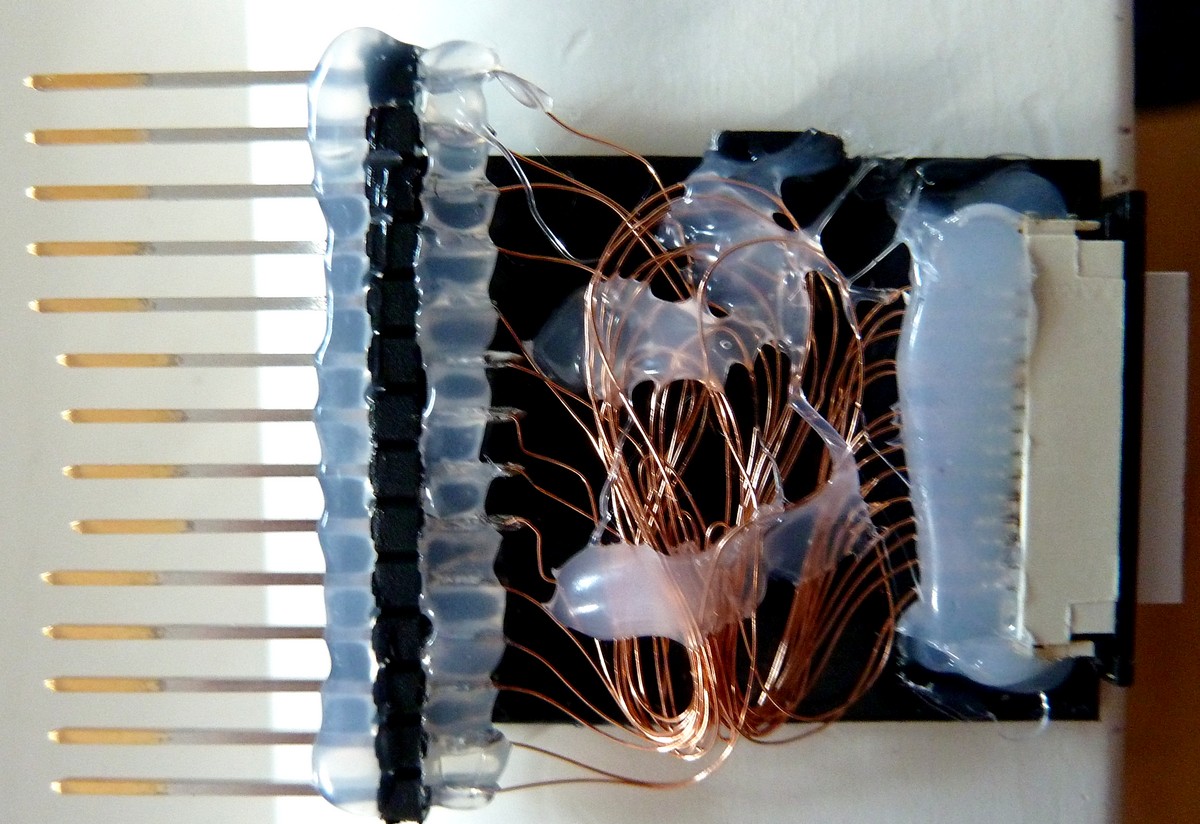

But what happens when you have a very strange high pitch connector that you would like to connect to your bread board? Per Jensen from Zapro shows us his solution here, he had a bunch of LCDs with a fine pitch ribbon cable that he wanted to use with his projects. Some very fine wire, a soldering iron with a pointy tip and nerves of steel is all that is needed to bridge between the flex cable and the breadboard pluggable pins. Since this fine wire could break with just the slightest movement, the most important thing to do is isolate the new fragile connections. Per uses some hot glue to stabilize the entire convertor so that it can be handled without the worry of the wires breaking, only issue here is you better be sure that you have it wired up exactly as you want it because unlike solder hot glue is hard to reverse.Â