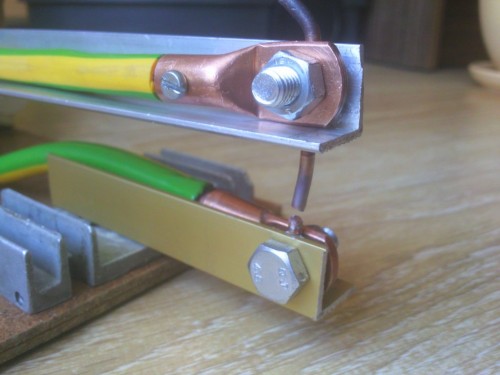

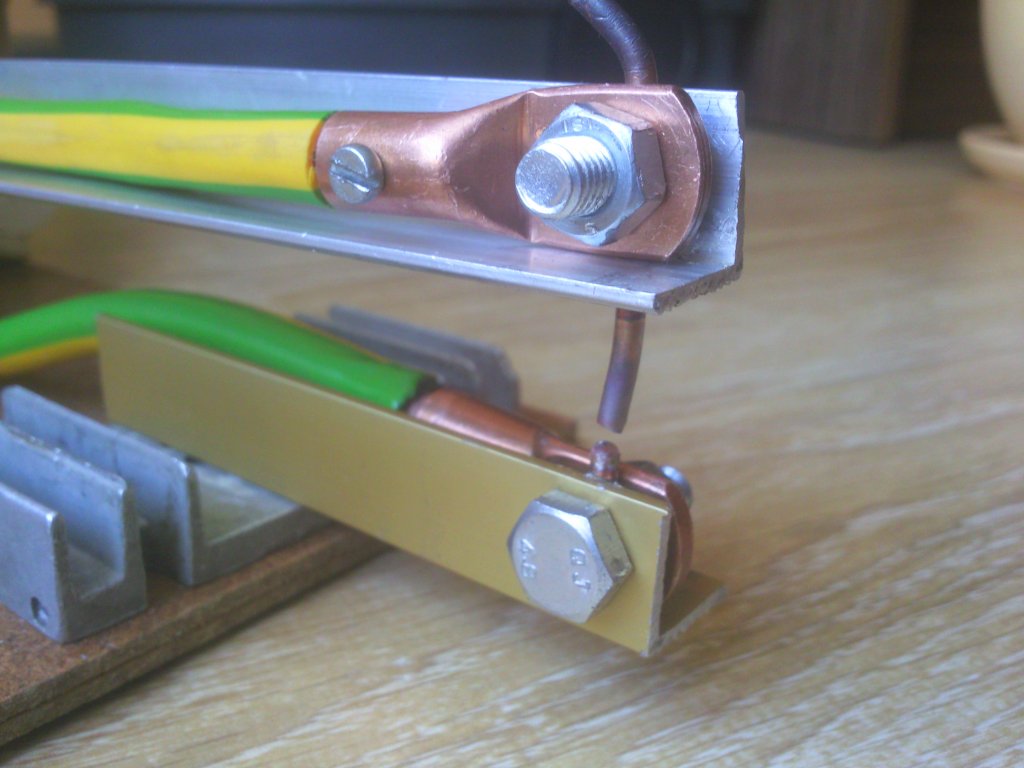

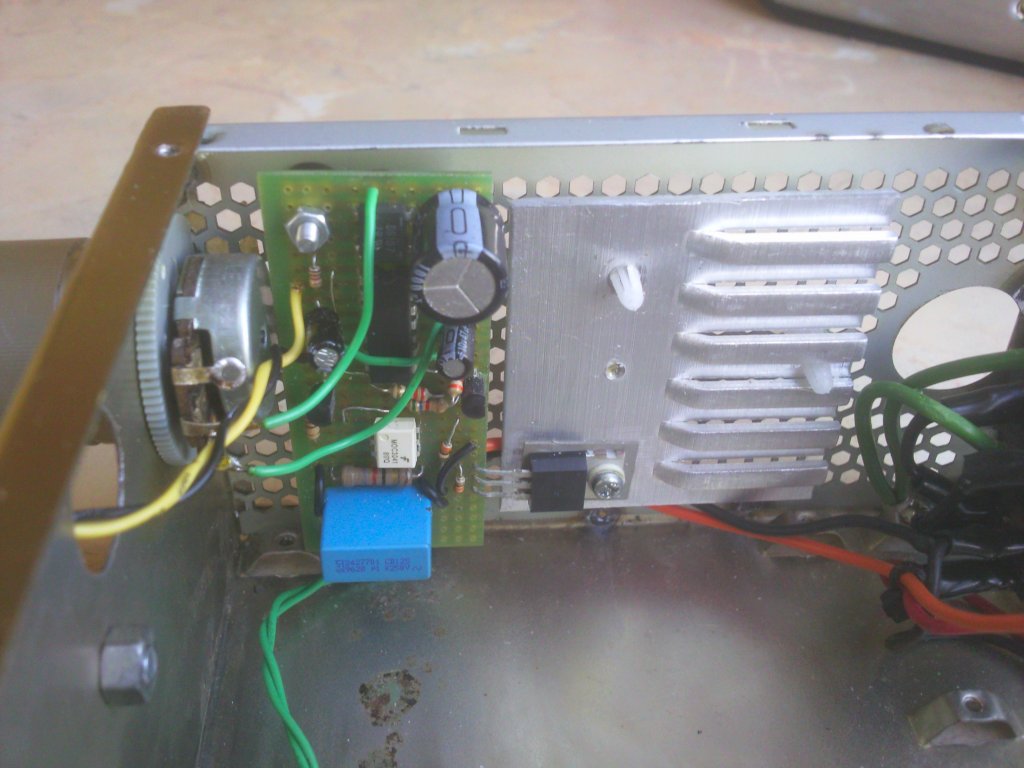

Using a transformer for an old audio amp and a case made from an old computer power supply sure does make for a good looking DIY spot welder. It also has some smarts built in to detect when the welding electrode has been lowered to allow for a slight delay before the welding power is turned on. A pot is adjusted to change the actual weld time so you can get it dialed in and produce consistent welds. Manekinen says that it can weld 2 x 0.75 mm sheets with no issues. A BT138 triac is used to switch the power and seems to be holding up but Manekinen would recommend using something a bit beefier if you decide to give the build a try.Â